Choosing the Right Galvo Head for Your Laser Handling Demands

Choosing the Right Galvo Head for Your Laser Handling Demands

Blog Article

A Comprehensive Overview to Galvo Motors and Their Effect On Laser Solutions

Galvo motors have arised as a critical component in the development of laser systems, supplying improved precision and performance across different applications. These gadgets help with fast positioning of optical components, which is vital for tasks varying from detailed engraving to complicated clinical procedures (Galvo). As innovation advances, the combination of closed-loop control systems and man-made knowledge guarantees to push the boundaries of what these electric motors can accomplish. Nonetheless, the implications of these developments expand past simple performance enhancements, questioning about future applications and market makeovers. What might this imply for the landscape of laser modern technology?

What Are Galvo Motors?

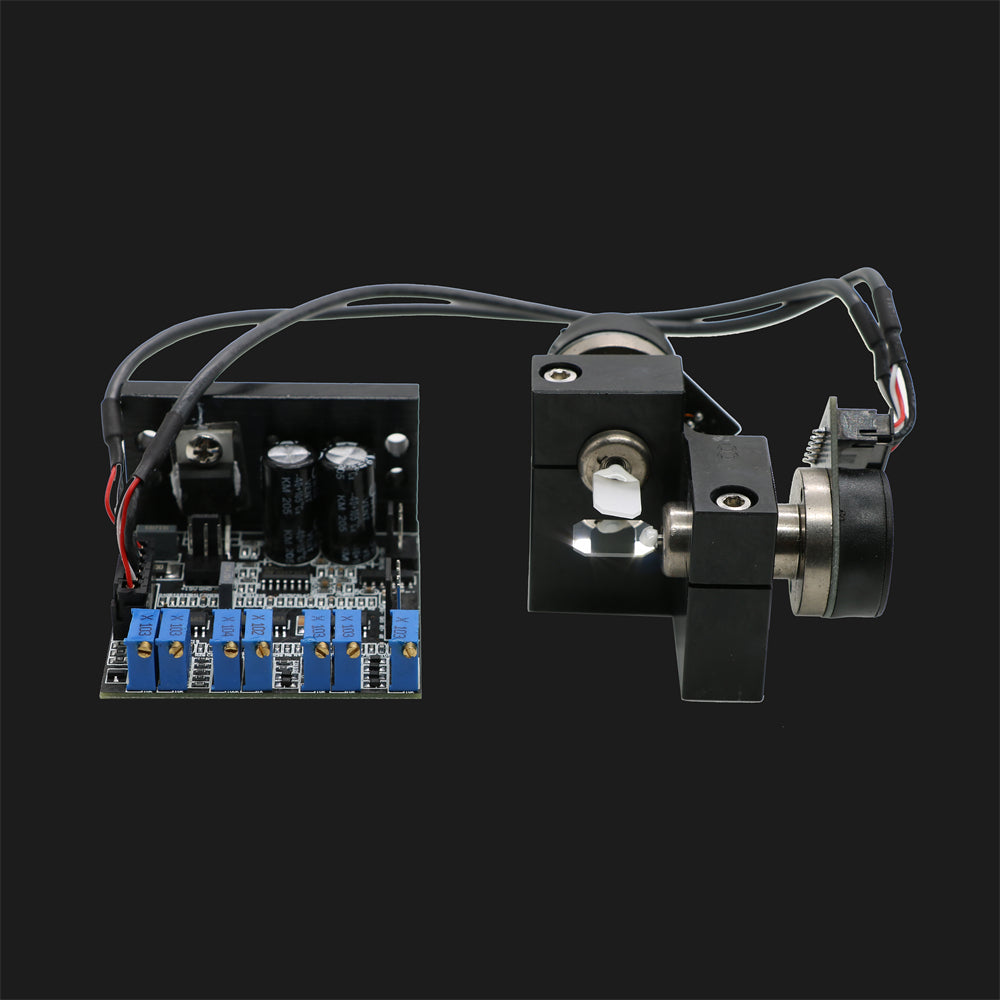

Galvo electric motors, brief for galvanometer motors, are precision gadgets used to control the setting of mirrors or lenses in laser systems. These electric motors are essential to various applications, consisting of laser engraving, cutting, and projection systems, where accurate positioning is important for optimal efficiency. Galvo electric motors utilize a light-weight style that enables quick motion, enabling high-speed procedure and precise control of laser beam of lights.

Furthermore, galvo electric motors can be incorporated with sophisticated control systems, enabling sophisticated shows and automation. This adaptability not only enhances functional effectiveness but also makes sure uniformity in output. As a result, galvo electric motors have actually ended up being an important element in modern-day laser innovation, facilitating advancements in different areas by allowing exact adjustment of light with unmatched rate and accuracy.

Just How Galvo Motors Run

The operation of galvo electric motors counts on precise electro-magnetic mechanisms that assist in rapid and exact positioning of mirrors or lenses. At the core of a galvo electric motor system are rotary coils installed on a shaft, which communicate with electromagnetic fields generated by irreversible magnets. When an electric current is used to the coils, it produces an electro-magnetic pressure that creates the shaft to turn. This turning is typically extremely quickly, permitting real-time adjustments to the angle of the mirrors or lenses.

Galvo motors are defined by their closed-loop control systems, which make use of feedback from position sensors to make certain accuracy. These sensing units keep track of the angular placement of the mirrors, relaying data to the controller that adjusts the present supplied to the motor. This comments loophole permits fine-tuning of the electric motor's position, causing high repeatability and accuracy.

Furthermore, the lightweight construction of galvo electric motors lessens inertia, allowing quick feedback times important for laser scanning applications. In general, the mix of electro-magnetic principles and closed-loop responses systems allows galvo motors to perform detailed tasks with remarkable accuracy and rate, making them indispensable in innovative laser modern technologies.

Benefits of Galvo Motors

Among the crucial advantages of making use of galvo electric motors in laser systems is their ability to attain fast and specific positioning, which is essential for applications such as laser inscription, cutting, and scanning. This precision is greatly due to the high-speed feedback of galvo motors, enabling them to swiftly adjust the angle of the laser light beam with minimal hold-up.

An additional considerable benefit is their minimized inertia compared to traditional stepper electric motors, which enables quicker velocity and deceleration. This particular not just improves the overall rate of laser operations but likewise adds to the top quality of the completed item by decreasing movement blur.

Applications in Laser Systems

Applications of galvo electric motors in laser systems span a vast variety of sectors, showcasing their convenience and efficiency. Primarily used in laser inscribing and marking, galvo motors enable specific control over the laser beam's placement, helping with detailed designs on different products such as metals, plastics, and glass. Their quick response times and precision significantly improve manufacturing efficiency, making them very useful in making processes.

In the realm of laser cutting, galvo electric motors permit high-speed operations, minimizing the time required for complex cuts while maintaining side top quality. This capacity is particularly helpful in fields like vehicle and aerospace, where accuracy is crucial. Galvo electric motors are instrumental in laser scanning applications, such as in 3D laser scanning like this and imaging systems, where they help with fast data purchase and analysis.

Medical applications likewise gain from galvo innovation, specifically in laser surgical procedure and analysis equipment, where precise beam control is critical for effective results. In enhancement, the appearance more tips here of laser-based micro-machining procedures has actually seen the fostering of galvo motors, boosting the capacity to perform fragile procedures with unrivaled accuracy. Overall, galvo motors play an important function ahead of time laser technology across varied areas.

Future Patterns in Galvo Modern Technology

Increasingly, improvements in galvo modern technology are positioned to change numerous markets that count on laser systems. One significant fad is the combination of man-made intelligence (AI) and machine understanding formulas right into galvo control systems. These innovations enhance accuracy and versatility, enabling real-time changes based on vibrant ecological conditions or material residential or commercial properties.

Another arising trend is the growth of higher-speed galvo motors, which assist in faster handling times in applications such as laser inscription and cutting - Galvo Motor. As industries require quicker turnaround times, these innovations will certainly end up being important for keeping competitive benefit

Furthermore, miniaturization of galvo parts is making laser systems much more flexible and compact. This pattern is specifically appropriate in fields such as clinical devices, where space restraints are extremely important.

Final Thought

Galvo motors have actually emerged as a that site crucial part in the evolution of laser systems, giving improved accuracy and effectiveness across different applications.Galvo motors, brief for galvanometer motors, are accuracy devices utilized to control the setting of mirrors or lenses in laser systems. Primarily used in laser engraving and marking, galvo electric motors enable specific control over the laser beam's placement, helping with intricate layouts on various materials such as steels, plastics, and glass. Galvo motors are critical in laser scanning applications, such as in 3D laser scanning and imaging systems, where they promote rapid information acquisition and evaluation.

As advancements in closed-loop control systems and synthetic knowledge integration continue to progress, the possibility for galvo electric motors to additionally change laser systems remains considerable, appealing raised speed and decreased movement blur, therefore expanding their utility throughout varied commercial fields.

Report this page